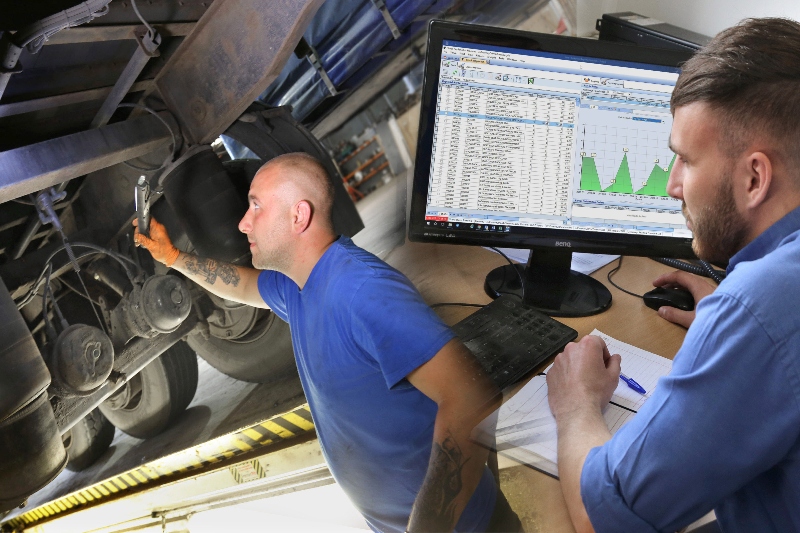

Freeway Fleet Systems has developed smart software that simplifies fleet management by predicting the type and quantity of parts needed to maintain a fleet.

Using Artificial Intelligence, the software works out future stock level requirements updating parts suppliers to automate stock replenishment and help eliminate out-of-stock occurrences.

The feature, which is incorporated in Freeway’s latest asset and workshop management system, continually learns from historic data to create a more accurate predictive model.

This includes identifying trends and anomalies such as fluctuating seasonal demand and likely extra demand for particular vehicles scheduled for servicing.

‘Fleet administration is a burden for operators and managing stock and purchasing is a particular challenge especially for mixed fleets where there may be individual parts running into the thousands,’ says Patrick Tandy, managing director of Freeway.

‘The switch to alternative fuels is only going to add complexity to fleet maintenance so we are continually looking at ways to simplify work through automation and the elimination of paperwork.’

With this software, workshop technicians can immediately request parts while on the job using electronic job sheets that identify the correct parts.

For defect rectifications requiring parts not held in stock, requisitions can also now be raised with one click to simplify and speed the ordering of the parts.

‘Our predictive purchasing development is an example of how Freeway’s software collects data and processes it to useful intelligence that can be used to improve the business,’ says Mr Tandy.

‘This added insight allows stock levels to be optimised, reducing unnecessary stock and by ensuring the right stock is always available. This, with faster requisition processing, helps ensure vehicle downtime is minimised.’